Client Objective: BIM model and drawings for more than 100-year-old Mechanical Room

A facility housed in a building over a century old required structural upgrades to its mechanical room. The primary challenge was that there were no existing drawings or CAD files that identified the layout or placement of structural elements such as steel beams and columns. The client needed accurate as-built data to integrate new structural components with the existing framework confidently.

Mechanical Room

Mechanical Room

Our Solution: High-Precision Digital Twin with LiDAR 3D Scanning

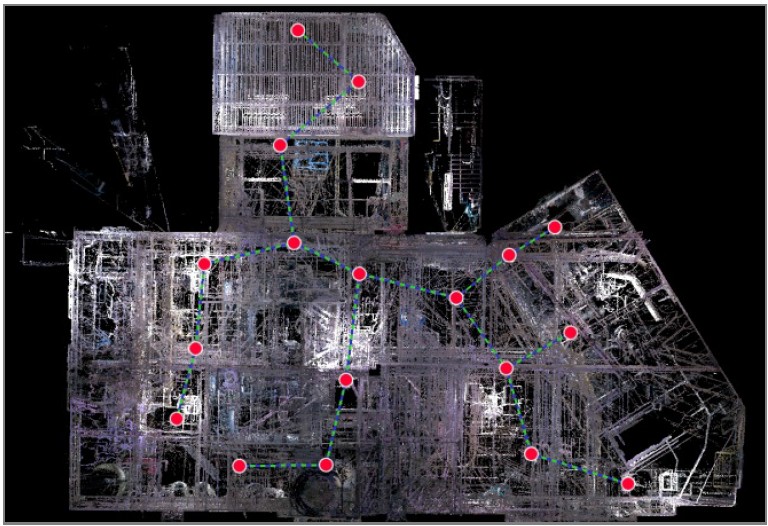

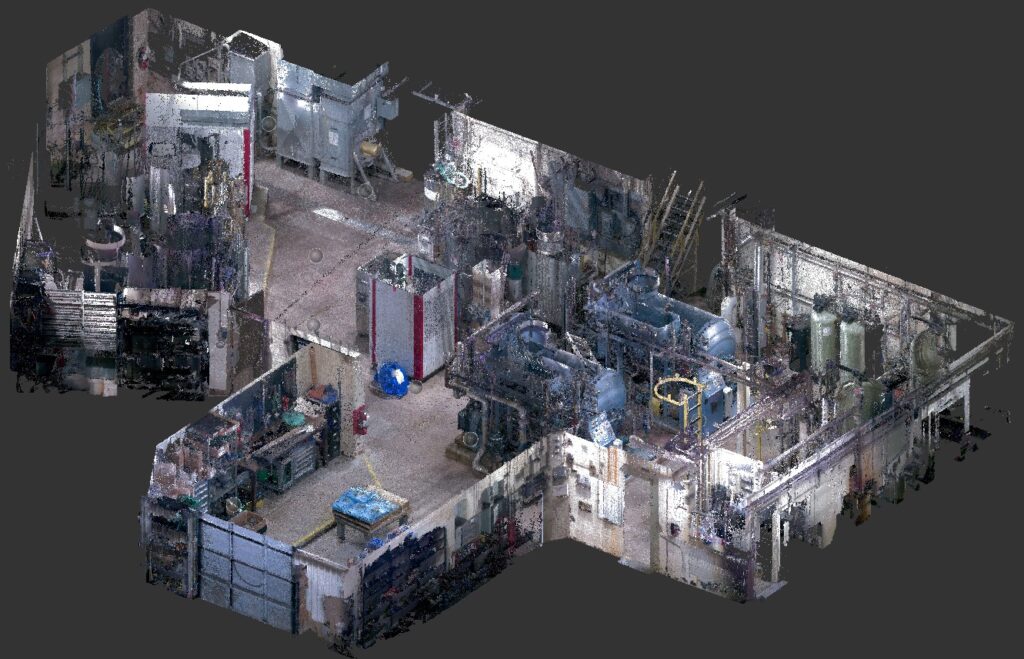

To overcome this challenge, our team deployed a LiDAR 3D scanner on-site. Following an initial site assessment, we strategically selected 18 scan positions to ensure full spatial coverage of the mechanical room. At each location, we captured high-resolution scans and corresponding real-view images and used the Field 360 app on our tablet to confirm data integrity in real time.

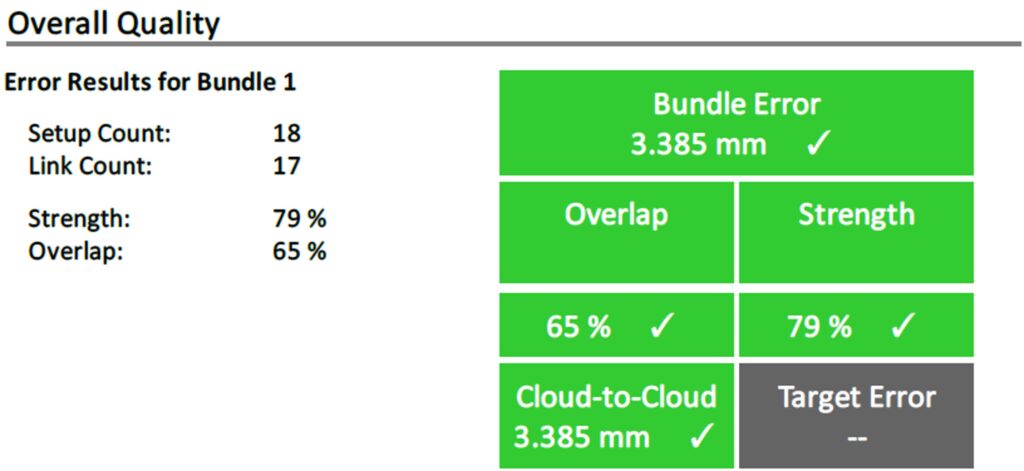

After collection, the scan data was imported into Leica Register 360 software. After meticulous review, all scans were precisely registered and combined into a unified, colorized point cloud—accurate to within a few millimeters. This point cloud served as a detailed digital twin of the mechanical room capturing as-built architectural and structural details as well as mechanical equipment therein.

Site map showing scanner locations (red dots) for each scan

Unified Point Cloud Registration Summary

Point Cloud Bundle (Digital Twin Model) of Mechanical Room

Point Cloud Bundle (Digital Twin Model) of Mechanical Room

Real view of Mechanical Room captured using LiDAR 3D scanner

From 3D Scan to 3D BIM CAD: As-Built Digitized

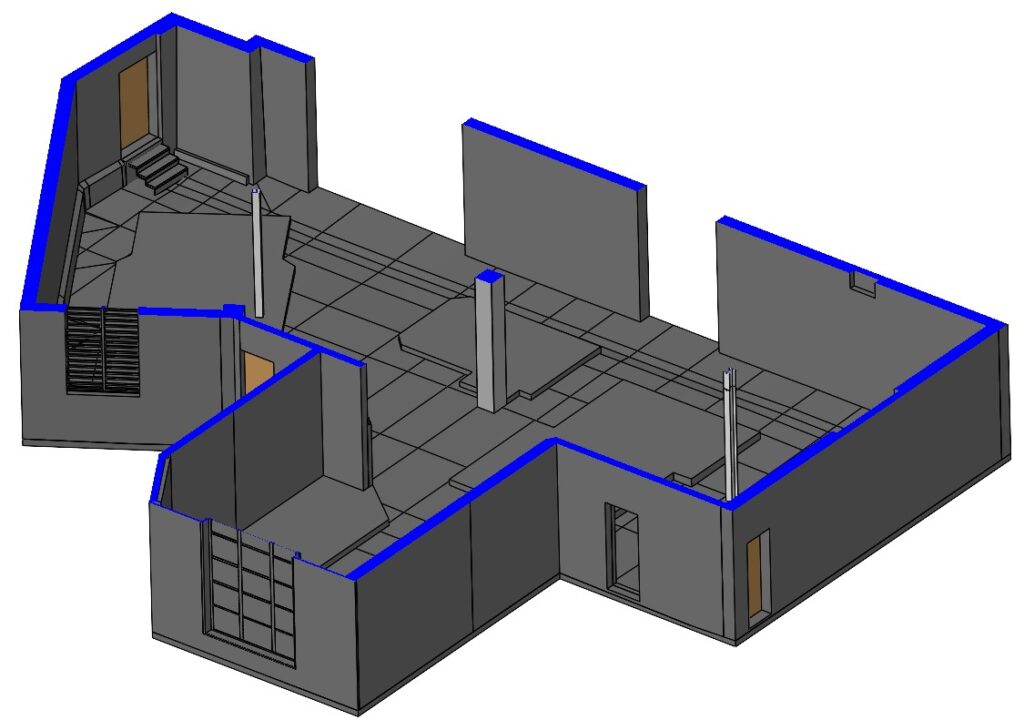

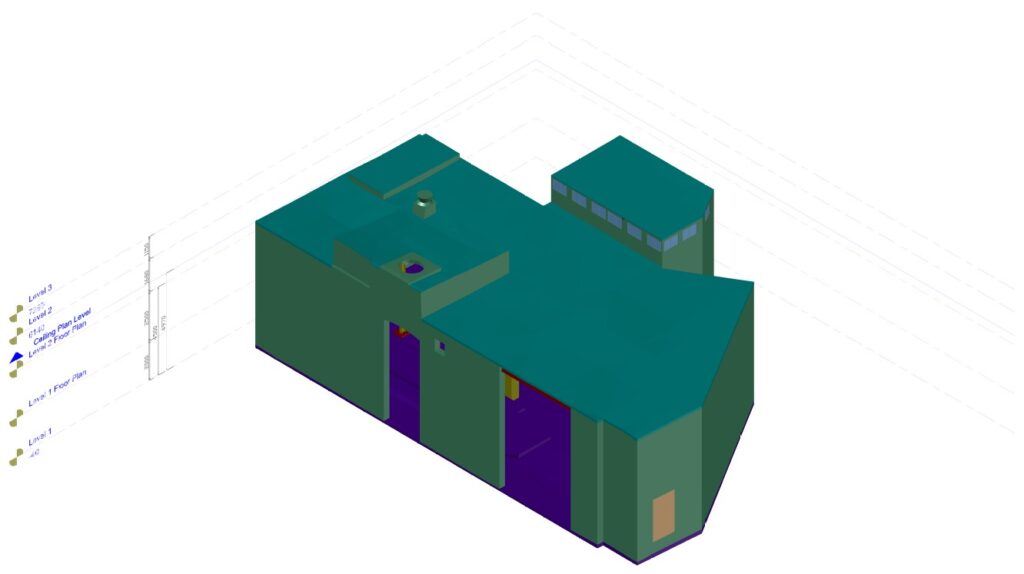

We exported the point cloud as an RCP file and imported it into Autodesk Revit to begin the modelling process. After setting reference levels, we modelled the architectural and structural features of the room to generate a comprehensive 3D BIM CAD model that represents as-built conditions.

BIM CAD Model of Mechanical Room

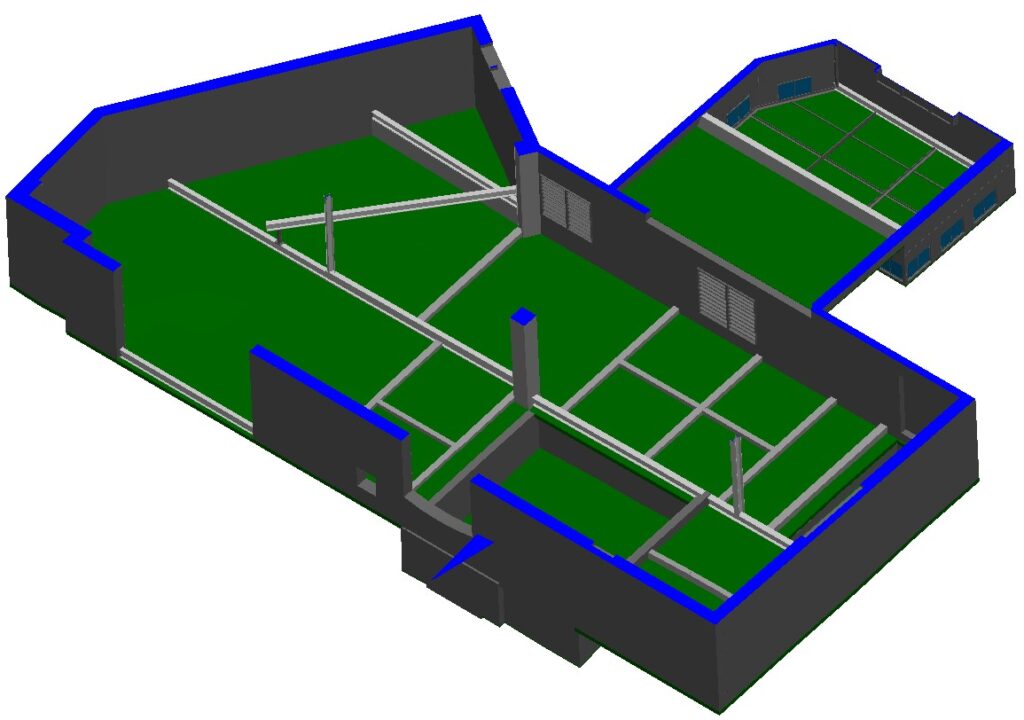

BIM CAD Model of Mechanical Room (ceiling view)

Using this model, we produced 2D documentation, including:

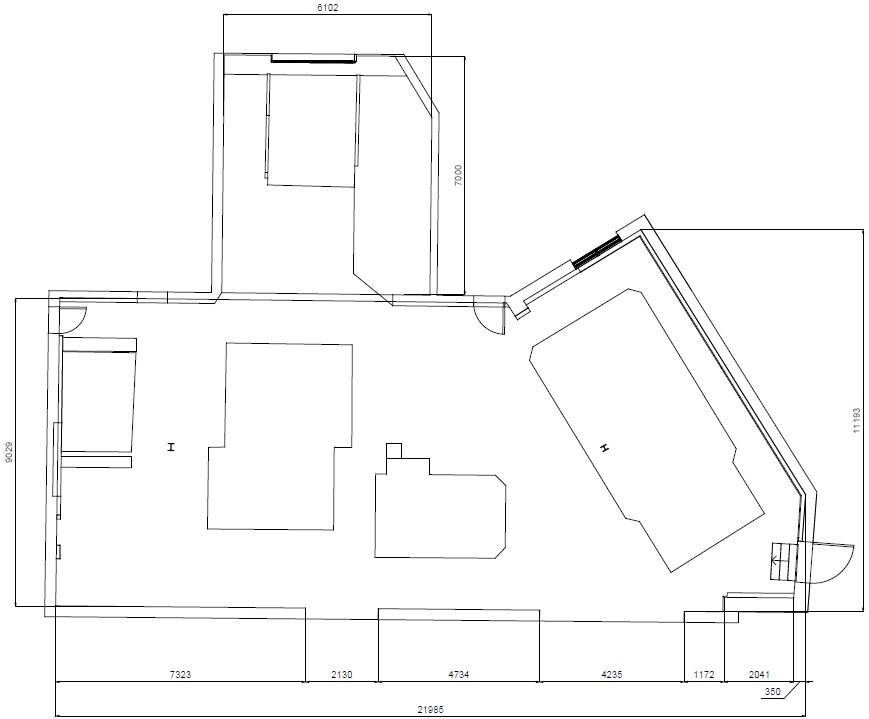

- Floor plans

- Ceiling plans

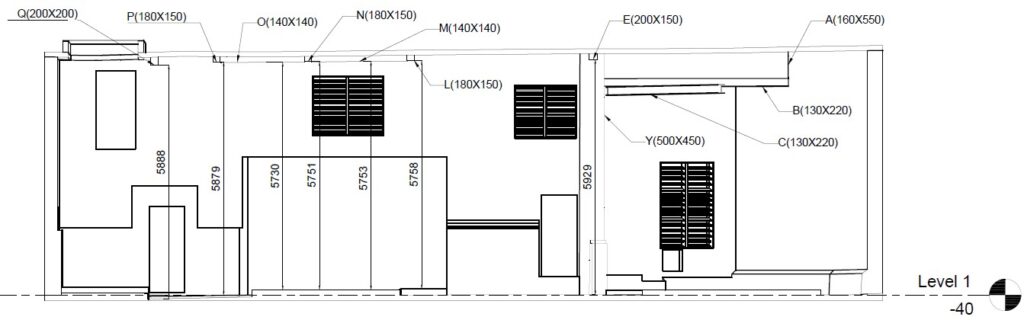

- Structural section views

- Tables listing structural element types and dimensions

These deliverables provided the client with a complete, CAD-accurate digital record of the space, ready for integration into their renovation plans.

Isometric View of Mechanical Room

Plan View of Mechanical Room

Section View of Mechanical Room

Conclusion:

Through LiDAR 3D scanning and BIM modelling, we delivered a precise, millimeter-accurate digital twin of a complex and aging mechanical room. This enabled the client to plan and execute structural modifications with confidence, eliminating guesswork and risk. Our solution ensured that new structural additions could be aligned seamlessly with existing steel beams and columns—transforming a data-deficient challenge into a digitally-driven success.