The Challenge: A custom car designer wanted to design a new headlight and corner light for a custom-designed car. It was extremely difficult to accurately measure the size of the lights and their mounting points which had to be in the same precise location in redesigned lights as compared to existing lights.

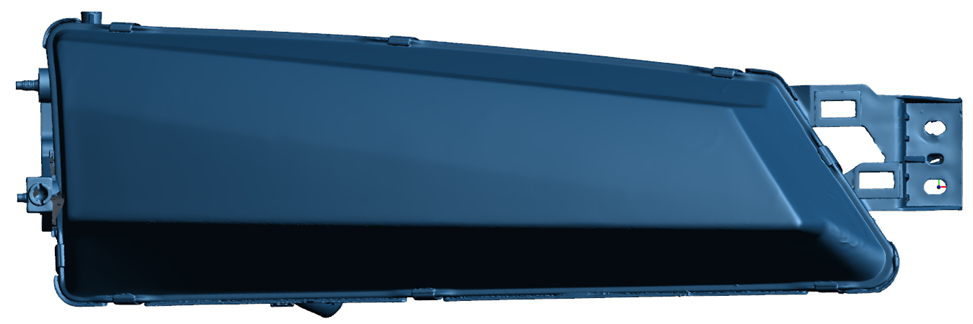

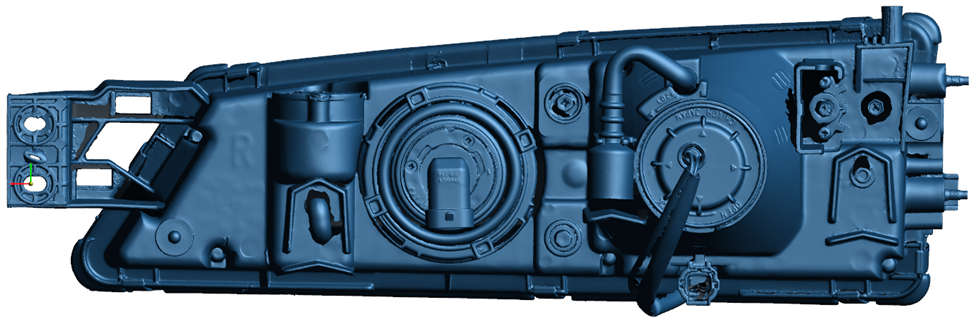

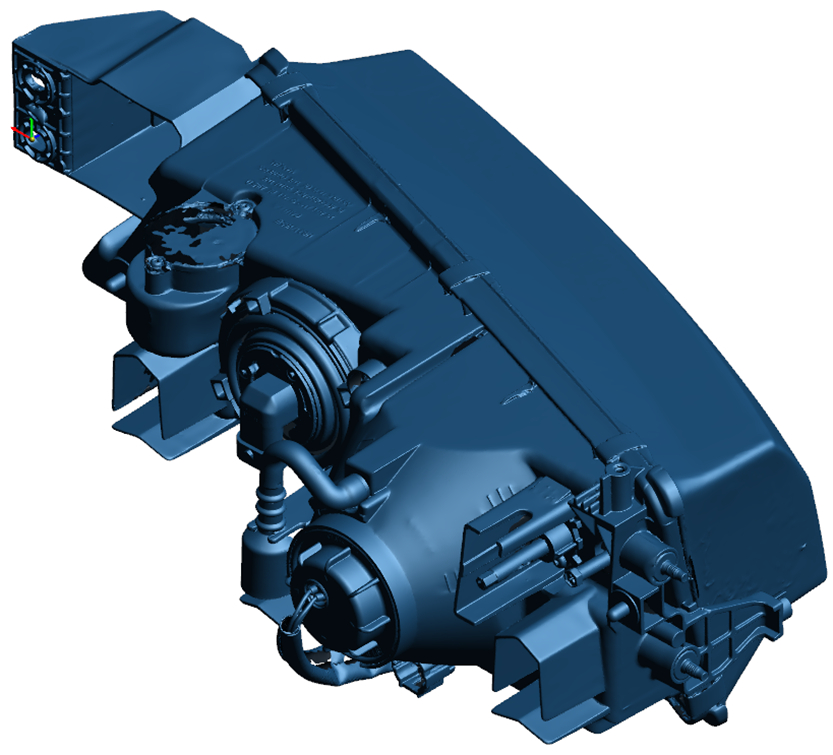

The Solution: V3D Technologies was able to provide the right solution for this issue and helped to accelerate the design of new lights. We accurately 3D scanned the lights using a certified metrology-grade laser 3D scanner. The transparent glass of the two lights had to be treated with sublimating 3D scanning spray that left no residue on the lights. Positioning targets were applied on the lights while scanning to maintain accuracy and generate a single scan of each light. The scanned polygon model of each light was aligned to the coordinate system in VXmodel. Necessary dimensions could now be extracted from the polygon model (scanned mesh) to design new lights that could be mounted to the existing car frame.

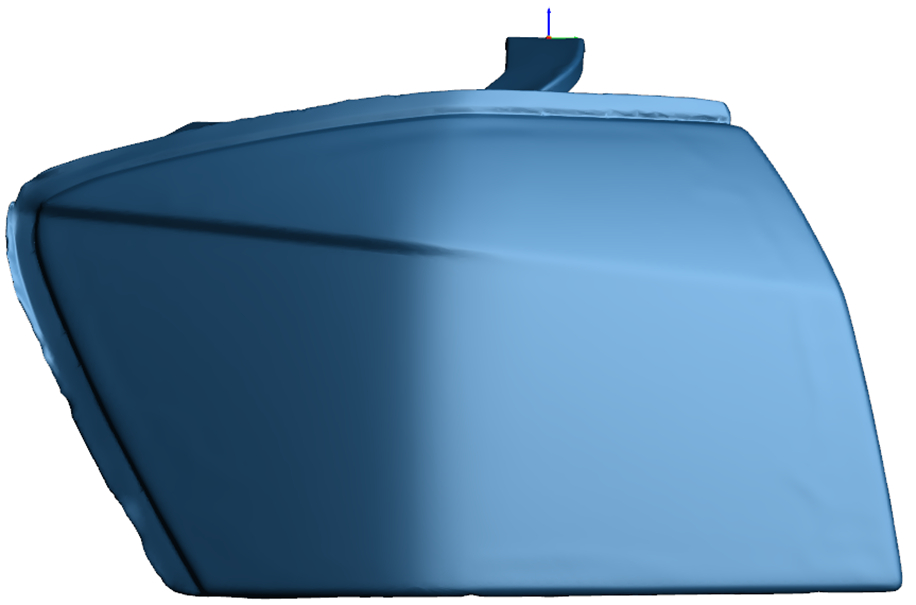

Polygon Model (scanned mesh) of Head Light

Polygon Model (scanned mesh) of Corner Light