Scanning Spray

3D Scanning Spray is used to treat the surface of parts before 3D scanning. Older methods would leave hard-to-clean residues. ATTBLIME developed a new generation sublimating scanning spray that does not leave residue, and as opposed to other scanning sprays available, does not contain titanium dioxide (TiO2), n-hexane or adamantine.

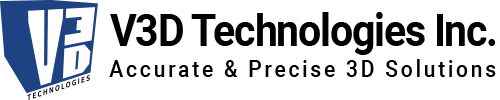

Comparison table

SHC system (SPRAY HEAD CHANGE SYSTEM)

The spray cans are equipped with the unique SHC system (spray head change system), which allows the user to control the layer thicknesses and thus sublimation times between vertical and horizontal, as well as wide and narrow exit angles.

Round spray head

Round spray pattern for high-resolution details. Shorter sublimation time thanks to a fine application.

Variable spray head (rotatable)

For a vertical and horizontal spray pattern. Longer sublimation time due to large-area application.

Extended spray head

Spray head with extended spray hose for hard-to-reach areas. This option guarantees a high level of detail resolution.

Sublimation technology

The raw material cyclododecane (CDC) contained in the sublimating scanning sprays does not bioaccumulate in water organisms and is therefore absolutely harmless for humans and for our environment. Due to its composition, CDC is much more economical than alternative products and does not require labelling according to the GHS “Globally Harmonised System”.

According to SGS Institut Fresenius, no cyclododecane could be detected 24 hours after an application of AB2 or AB6 and 96 hours after an application of AB24. Visible contamination is no longer present.

The pigments contained in the permanent scanning spray ABP are based on renewable natural raw materials.

The versions ATTBLIME ABX, AB2, AB6 and ABP are also available in bulk container form of 1,000ml or 5,000ml.