The Challenge: Suppliers sometimes discontinue manufacturing of certain models with no replacement offered or their lead times for replacement parts are extensively longer which severely impacts current users & businesses. One of our customers found themselves in a similar situation with reflectors and decided to manufacture their own reflectors to meet their needs. However, no CAD model of existing reflectors was available from the original manufacturer. Manual measurement of reflectors was too cumbersome to create an accurate CAD model.

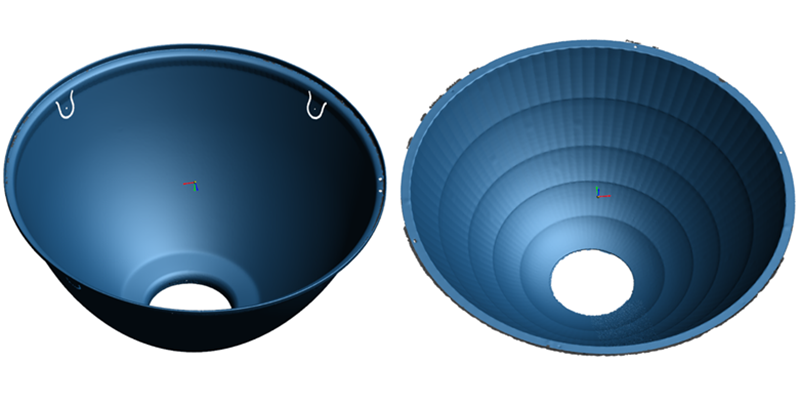

The Solution: V3D Technologies was contacted for the solution to the problem. We had the right tools, knowledge, and experience to offer the perfect solution to our client. Using a certified metrology-grade 3D laser scanner, we accurately scanned the two reflectors. Positioning targets were applied to the surface of the reflectors to create a single polygon model that captured the entire geometry of the reflectors including the thickness. With our 3D laser scanner, there was no need to apply any matting agent to the reflective surfaces to scan them completely.

Polygon Model (scanned mesh) of Reflectors

Polygon model generated by the scanner is randomly positioned in space. Therefore, the first step is always to align the polygon model to the global coordinate system. This step was done in VXmodel software.

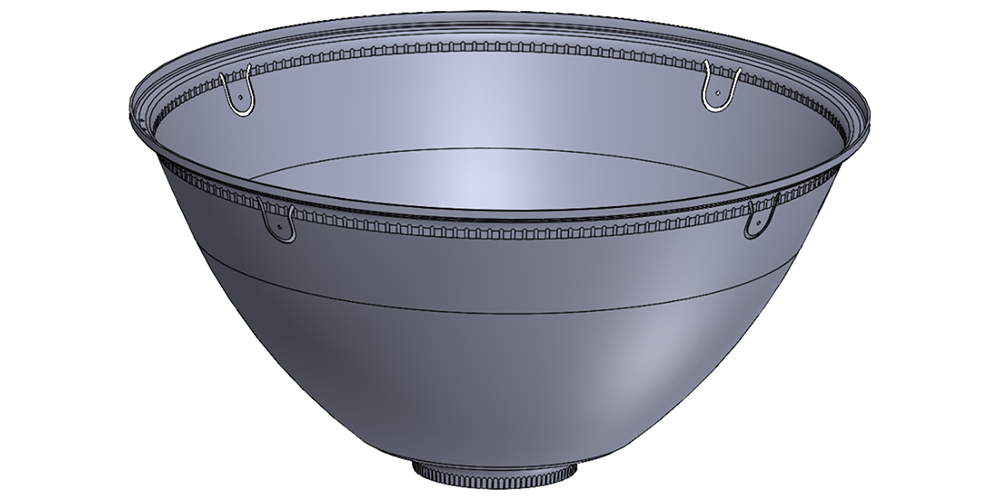

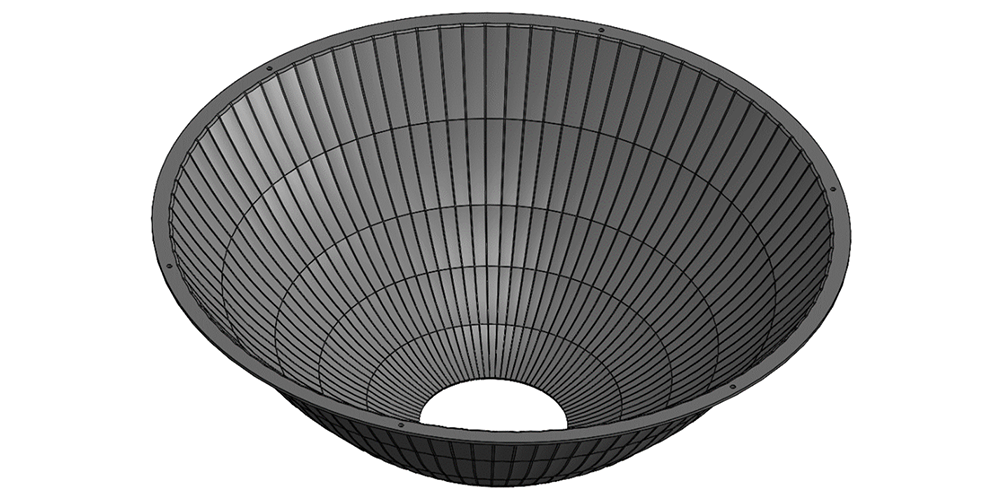

Next, we transferred the aligned polygon mesh to a dedicated scan to CAD reverse engineering software. Here we created cross-sections referencing the polygon mesh and created a parametric CAD model for each reflector.

Parametric CAD models of Reflectors

Conclusion: 3D laser scanning helped convert physical reflectors to digital CAD format in no time as compared to traditional manual methods. Our seamless scan to cad process helped our customer produce parts as required.