In industries where precision is paramount, the accuracy of measurements can make all the difference. From manufacturing and engineering to healthcare and aerospace, organizations across various sectors rely on precise measurements for quality assurance, product development, and performance optimization. This is where 3D metrology steps in, offering a revolutionary approach to precision measurements. In this blog post, we will explore the numerous benefits of using 3D Metrology for precise measurements and how it transforms industries.

Enhanced Accuracy

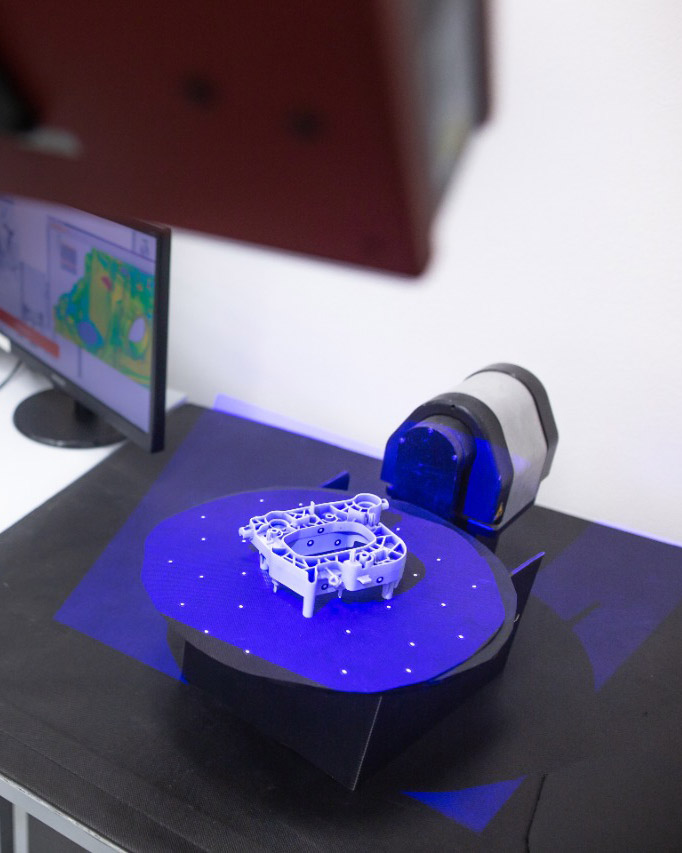

One of the primary advantages of 3D metrology is its ability to provide highly accurate measurements. Traditional measurement techniques often have limitations, but 3D metrology allows for more comprehensive and precise data capture. By utilizing advanced technologies such as laser scanners or coordinate measuring machines (CMMs), 3D metrology ensures precise measurements of complex geometries, contours, and surfaces.

Improved Efficiency

3D metrology streamlines measurement processes, leading to improved efficiency. With automated data collection and analysis, measurements can be performed quickly and accurately, reducing the time and effort required for manual measurements. This increased efficiency enables organizations to accelerate their production processes, reduce downtime, and make informed decisions in a timely manner.

Quality Assurance and Inspection

In industries where quality control is crucial, 3D metrology plays a vital role. It enables comprehensive inspection and verification of products, parts, or components, ensuring they meet precise specifications and tolerances. By identifying deviations or defects early in the manufacturing process, organizations can proactively address issues, minimize rework or scrap, and maintain consistent quality standards.

Complex Geometric Measurements

Certain industries deal with complex geometries that demand advanced measurement capabilities. 3D metrology excels in capturing intricate shapes, freeform surfaces, and multi-dimensional features that may be challenging to measure using traditional methods. This capability is particularly valuable in industries such as automotive design, aerospace engineering, and medical device manufacturing.

Data Visualization and Analysis

3D metrology generates detailed and visual representations of measured objects, facilitating in-depth analysis and decision-making. Advanced software tools such as Polyworks Inspector enable the visualization of measurement data in 3D models, allowing for better understanding, trend identification, and process optimization. Data-driven insights derived from 3D metrology support continuous improvement efforts and facilitate innovation.

Non-Destructive Testing

In many applications, preserving the integrity of the measured object is essential. 3D metrology offers non-destructive testing capabilities, allowing measurements to be taken without causing damage to delicate or valuable components. This feature is particularly valuable for industries, where artifacts need to be measured and analyzed without altering their original state.

At V3D Technologies, we specialize in delivering advanced 3D metrology solutions tailored to meet the specific needs of diverse industries. Contact us today to learn more about how our cutting-edge technology can revolutionize your precision measurement processes.